Engineering Approach to Make the Bio Fertilizer Use a Reality

By Eng. Ruwan Nagahawatta

Sri Lankan economy was estimated to be $84 billion by nominal gross domestic product (GDP) in 2019 and $296.959 billion by purchasing power parity (PPP). Though there is a competitive export agricultural sector available for Sri Lankan farming community to catch up with growing global insecurity in food supply chain, practical policy frameworks are not in place for agriculture sector to transform their working model to value added product manufacturing and export. Meantime Sri Lankan government had taken a very challenging policy decision to convert it chemical fertilizer use to bio fertilizer use within very short period of time. The Government had established a task force that would ensure production of organic fertilizer which would be used in the agriculture sector. The organic fertilizer program that is going to start in near future is expected to replace the annual sum of USD 400 million spent on fertilizer imports.

It is well known fact that the controlled usages of chemical fertilizers help for a better harvest and good economic return for farmers. However, due to government subsidiary mechanism, Sri Lankan farmers are used to apply heavy fertilizer dose for in farming activity hoping much better harvest in every season. The heavy dosage of chemical fertilizers for many years had polluted the lakes, canals and groundwater outweighing the profits of better harvests. As per the health sector finding, the uses of chemical fertilizers have significant correlation to a number of non-communicable diseases, including kidney diseases.

Chemical Fertilizer Role in Food Production and Sri Lankan Fertilizer industry

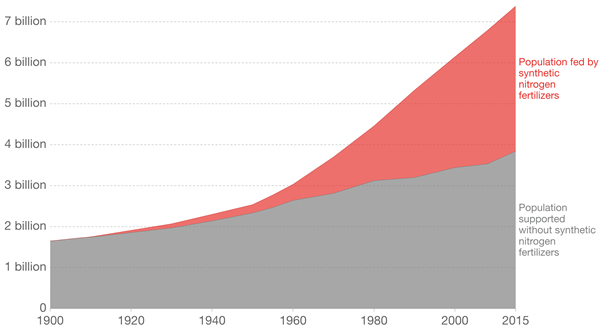

Chemical fertilizers play an important role in world food production and have been able to provide the necessary boost for the world food production to feed the 7 billion people. Hence we need to understand the demand of food production for the country and reduction in harvest in absence of chemical fertilizers before we activate the total chemical fertilizer ban. Below graph indicate the support that chemical fertilizers were given in feeding the population of this world.

Figure 1 : Fertilizer types and their contribution towards feeding the world population

Figure 1 : Fertilizer types and their contribution towards feeding the world population

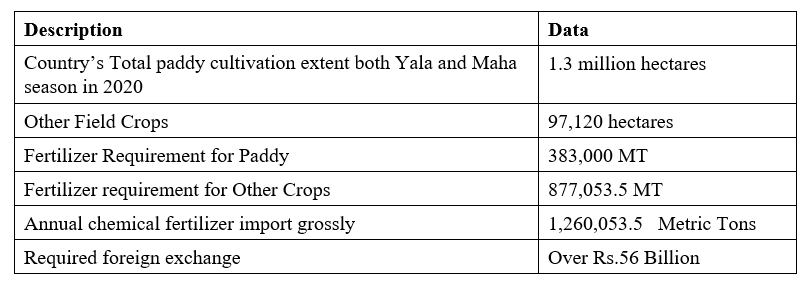

In parallel to the development of advance chemical fertilizers, Sri Lanka also import chemical fertilizer for agriculture and distribute after granting huge subsidies on price. The import data highlighted that we as a country import 265,000 metric tons of Urea, 65,000 metric tons Triple Super Phosphate (TSP) and 75,000 metric tons of Muriate of Potash (MOP) for a season and annual expenditure of chemical fertilizer import is in excess of 35 billion Rupees.

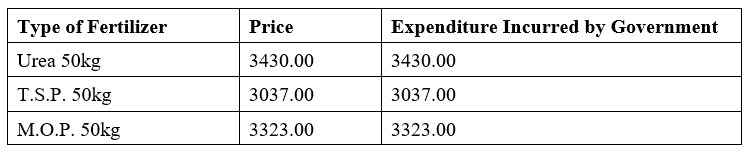

Distribution of fertilizer imports for year 2020 can be illustrated in below tables

a) Paddy

Table 2 : Financial impact on Fertilizer Subsidiary for Paddy Cultivation

Table 2 : Financial impact on Fertilizer Subsidiary for Paddy Cultivation

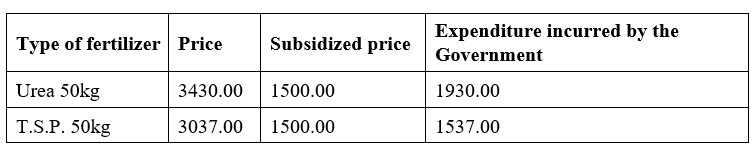

b) Cultivation of Other Crops

Table 3 : Financial impact on Fertilizer Subsidiary for Other Crop Cultivation

Table 3 : Financial impact on Fertilizer Subsidiary for Other Crop Cultivation

The comparison of Fertilizer uses by regional and developed countries could be illustrated as follow to showcase the dependency of Sri Lankan agriculture sector in chemical fertilizers.

Table 4 : Chemical Fertilizer Use by Country

Table 4 : Chemical Fertilizer Use by Country

Even though the excessive use of chemical fertilizer had not being able to increase the harvest substantially, it has led to blind childbirths and many health issues amoung Sri Lankan population. The scientific studies conducted to understand the causes of wide spread Kidney and Cancer patients in the country had identified, that the excessive fertilizer use resulted in poisoning the soil with chemical ingredient and subsequently effected the people.

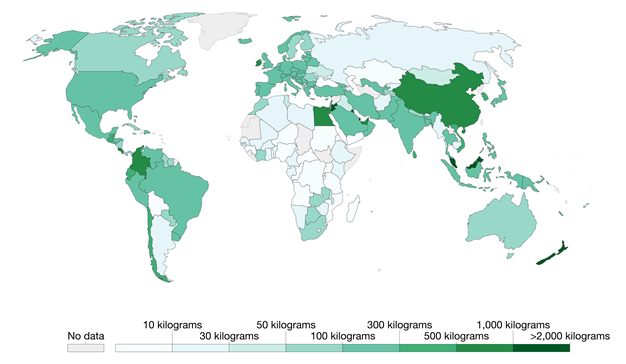

Figure 2 : World Fertilizer Usage

Figure 2 : World Fertilizer Usage

The above colored geographical map represents chemical fertilizer use in the world and the position of our country in the world in terms of fertilizer usage. The use of chemical fertilizer for the agriculture field is to be decided upon the soil textured that is monitored through scientific means. Even though soil-testing equipment are made available with Agrarian Services Centre (in more than 500 centers) it was noticed that scientific approach in agriculture is very unpopular topic among officials and farmers. Also since the fertilizer supply becomes political tool, farmers tend to overdose the soil with chemical fertilizers that are distributed under heavy subsidies creating problems for our future generations.

Current trend in the world is to use both organic fertilizer and chemical fertilizer in crop cultivation. It was scientifically proven that less organic materials absorbed fewer nutrients and most of the chemical fertilizers used in the field are not retain in the soil. Hence organic fertilizers are need to promote to use as soil conditioner to improve the organic content in the agriculture fields, that will result in increasing the capacity of soil to hold more nutrients and resulting less demand for chemical fertilizers

Why Bio Fertilizers are Important in Agriculture

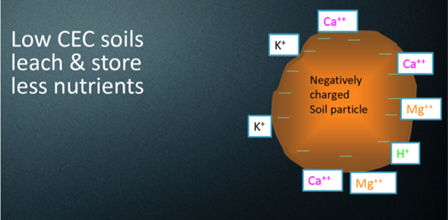

The soils provide the base for the plant to grow and it generally contains organic materials and clay that are negatively charged and that is vital for retention of high amount of nutrients. Generally the Bio fertilizers fulfill the duties of negatively charged particles and help to increase the effectiveness of the chemical fertilizer use.

Figure 3 : Importance of Compost

Figure 3 : Importance of Compost

Compost as a Bio Fertilizer

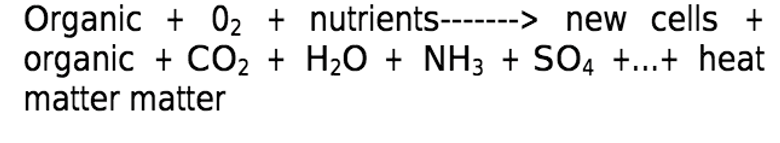

Composting is simply the enhancement of the natural biological degradation of organic matter, Microorganisms converts the organic matter into humus-like material. The product is more commonly known as compost. The following general formula illustrates the inputs and outputs for the conversion of organic matter in the presence of oxygen.

Compost is a mixture of decayed organic material decomposed by microorganisms in a warm, moist, and aerobic environment that release nutrients into readily available forms for plant use. Among these microorganisms, fungi like Trichoderma spp. Pers. are important microbes that help in decomposition of organic material and are known as “compost fungal activator” (CFA). Trichoderma spp. produce hyphae which are branched, creeping, forming a tuft or cushion on natural substrate, septate; conidiophores are erect, indefinite, arising from short branched side branches, bearing phialides laterally and terminally; phialides are surrounded by heads, rarely by short chains of slime spores; conidia are hyaline or bright coloured, one celled and chlamydospores are terminal or intercalary.

Status of Compost Production in Sri Lanka

In the South Asian countries except Sri Lanka use composting technology to reduce 16% of organic waste generation in day today life into bio fertilizers. However in Sri Lanka, the adaptation of composting technology is as low as 2% and most of the organic waste collections in urbanized areas are send to landfills. Hence as a country we have a great potential to increase the compost making process practices using solid waste disposal from households. Most of the composting practices that were adopted in country today are based on conventional wind raw technology and the system of wind raw has a very poor yield and nutritional values compared to the advance composting technologies available today.

Many local authorities in Sri Lanka had ventured into the compost manufacturing process as a solution for the waste disposal for their urban councils. However most of the projects has been abandon or operating with large difficulties in encountering following environmental issues and public pressure against the project operation.

- Composting process will take 3-4 weeks

- Attract pests

- Emit odor creating public nuisance

- Leachate generation

- Difficult to handle indoor

- Need large space

- Labor intensive

Figure 4 : Wind- Raw exposed Compost Plant - CEA

Figure 4 : Wind- Raw exposed Compost Plant - CEA

Figure 5 : Wind- Raw Compost Plant _ Inside arrangement

Figure 5 : Wind- Raw Compost Plant _ Inside arrangement

Advancement in Composting Technology

The natural composting processes depend on the healthy growth of microorganism of mesophilic bacteria to break the natural organic compounds and convert it to soil enriching material called compost. However the process takes 3 to 4 weeks due to speed of natural growth rate of bacteria.

The rapid composting is an adaptation of natural composting process that has the ability to enhance the environment within the biodegradable material to initiate an accelerated growth of microorganisms within the raw materials and completing the conversion of biodegradable materials to compost at much faster rate than the usual process.

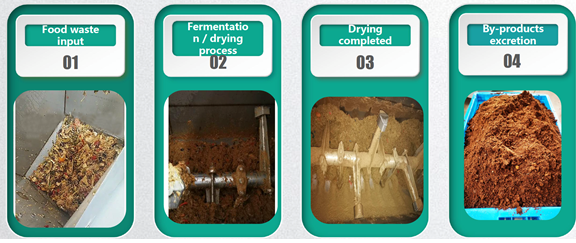

This technology utilizes external heat, aeration system and nutrition balance in the feeding material for the microorganisms to develop and multiply at exponential rate that could decompose organic materials within very short time. Generally in rapid composter, the whole process of making compost from the raw material could be completed within 20 hours. This is a batch process and the output material is readily usable for the agriculture for the soil enrichments.

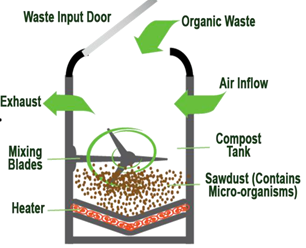

Rapid composter is equipped with rotary arms that are used for mixing of raw materials. It also supports the aeration process of raw materials. The aeration activity in the machine helps aerobic bacteria to grow healthy and to multiply at rapid rate and decompose the feed materials as the first stage of this race. However the aerobic bacteria that grow at the initial phase of the composting processes are very sensitive to the temperature and as the temperature increase in the reaction chamber, thermophilic bacteria takeover the decomposing work until the end of the process. The conversion proposes is discuss in more details below.

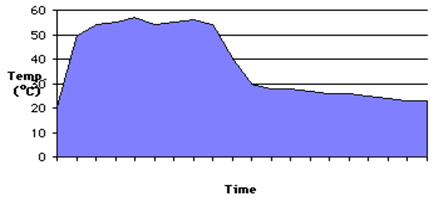

Figure 6 : Temperature Vs time in rapid composting process

Figure 6 : Temperature Vs time in rapid composting process

At the beginning of the composting process (0-40°C), mesophilic bacteria predominate. Most of these are forms that can also be found in topsoil and depend on aeration for their survival.

As the compost heats up above 40°C, by external support and due to the chemical activities of mesophilic bacteria, the thermophilic bacteria take over the duties of decomposing activity. Members of the genus Bacillus dominate the microbial populations during this phase. The diversity of bacilli species is fairly high at temperatures from 50-55°C but decreases dramatically at 60°C or above. When conditions become unfavorable, however bacilli survive by forming endospores, thick-walled spores that are highly resistant to heat, cold, dryness, or lack of food. They are ubiquitous in nature and become active whenever environmental conditions are favorable.

Even though the bacteria does major part of rapid composting, the success of rapid composting process would also depend on maintenance of following parameters within the reaction chamber and feed materials

- Adequate air space – 55-65% of Free air space by volume

- Moisture content- 40-65%

- Incoming materials size- 4-50mm

- Proper mix of carbon and nitrogen

- Healthy micro organisms

The carbon to nitrogen ratio is very important because it determine how easily the bacteria are able to decompose the organic materials. The micro organisms in compost use carbon for energy and nitrogen for protein synthesis similar to human use of carbohydrates for energy and protein to build and repair bodies. Optimum carbon to nitrogen ratio is 30:1. However the composting process could operate the carbon to nitrogen ration from 25:1 to 40:1.

Figure 7 : Conceptual Diagram of Rapid Composting Unit in Operation

Figure 7 : Conceptual Diagram of Rapid Composting Unit in Operation

The concept of rapid composting is first developed in Japan in year 1981 and then the technology being transferred to the various part of the world. Today, China, India and South Korea are leading in this technology with adaptation of modularization and automations.

Figure 8 : Steps of Rapid Composting Unit in Operation

Figure 8 : Steps of Rapid Composting Unit in Operation

The Rapid composting technology is the newest addition to the organic solid waste disposal that has ability to reduce the time taken in completing the composting process. With the development of rapid composting technology world has better chance of supply of organic fertilizers that is suitable for agricultural use.

Rapid Composting Experience in Sri Lanka

Oldest rapid composting unit operating in Sri Lanka is installed in office to process the collection of organic solid waste disposal of 150 employees. The pilot unit is in operation since 2017 on the principal of rapid composting and it converts the organic waste in to bio fertilizer. The organic content of the converted food waste will enrich the soil with its organic fertilizer. With the adaptation of new technology, the company was able to reduce the daily organic waste by 80%. The unit was tested for 4 years in-house before commercialization to understand the effective use of rapid composting technology for the organic waste disposal. All the organic fertilizers generate by the machine are used for landscaping and agricultural use.

Figure 9 : Composting Unit in Operation in Sri Lanka

Figure 9 : Composting Unit in Operation in Sri Lanka

Availability of Bio Degradable Materials for Bio Fertilization

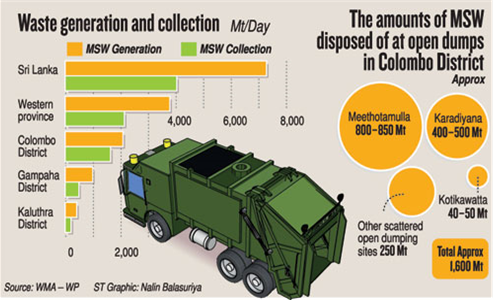

Today Sri Lanka has a total solid waste generation in excess of 7000 Mt per day and only 60% of the total waste generation is being collected. All major cities in Sri Lanka are struggling with resources in managing the daily garbage collection and as it goes to rural area the collection is as low as 25%.

Figure 10 : Waste Generation and Collection

Figure 10 : Waste Generation and Collection

The growing quantity of solid waste collection in all parts of Sri Lanka , create greater opportunity for the investment in the bio fertilizer field. The less use of polythene, plastic and other non-bio degradable Martials in Sri Lankan rural sector further enhance the opportunity for decentralized installation of bio fertilizer units in selected agricultural sectors in Sri Lanka.

Generally, biodegradable materials of the waste collection consist mainly of food waste, vegetable and fruit market waste; leaves and green disposals from homes and various fast perishable wastes dispose from domestic and commercial places. The biodegradable has the nature of decomposing fast and high emission of smell. General public highly resist disposal of organic waste near to their residence mainly due to the unpleasant smell and tendency to attract other animal and pest. Hence the concept of solving the waste problem should be able to solve the issue of odor and pest attraction.

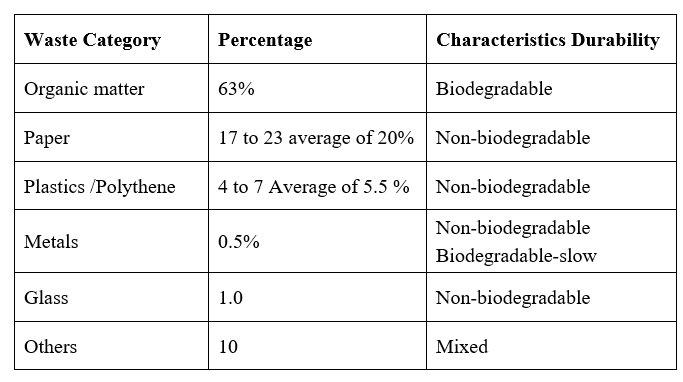

Waste generation in Sri Lanka has a its variation from district to district as on living pattern of that area. However the most challenging waste compositions are collected within the city of Colombo with high variation of consumer pattern. The composition of the waste collection in Colombo can be given as for below data.

Table 5 : Composition of Typical Urban Solid Waste

Table 5 : Composition of Typical Urban Solid Waste

So it is very potent to invest in bio fertilizer project considering the large resource of biodegradable materials for the use of bio fertilizer production.

Compost for the Future

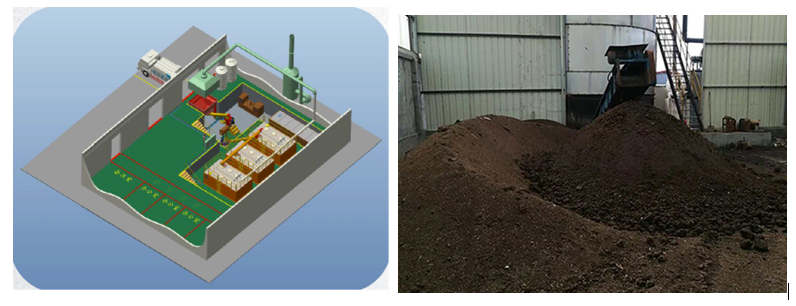

Figure 11 : Proposed Regional Composting Site for Urban Council

Figure 11 : Proposed Regional Composting Site for Urban Council

The agriculture sector in Sri Lanka provide livelihood for 24% of total work force and their families and contribute 7.4% in GDP. The bio fertilizer use in agriculture creates opportunity for engineers to mechanize the production of biofertilizers and help government in winning the goal of sustainable farming. Original plan of government was to increase the use of organic fertilizer up to 30% within the next 03 years.

However government had switch gears and enter into a phase that the agriculture will be switch to the biofertilizers within a period of once year. The biofertilizer uses reduce the dependency on imports of chemical fertilizers. However looking at the conversion efficiency, scalability, reuse percentage, and environmental friendliness the rapid composting is an ideal technology for solving the problem of Bio fertilizer shortage and indirectly it will also help in solving the solid waste disposal problem of the country.

If Government set correct policies and use correct technology adaptation with mechanization of bio fertilizer industry, Sri Lanka could be able to save more than 20 billion Rupees to the economy that was previously spent on solid waste disposal management and USD 400 million that used for importation of chemical fertilizer.

References

- Ministry of Agriculture, Sri Lanka

- World Bank-OurworldData.org/Fertilizer

- Compost Microorganisms by Nancy Trautmann and Elina Olynciw

Eng. Ruwan Nagahawatte has more than 15 years of experience in designing, construction and operation of power generation system in Sri Lanka. He is graduated from University of Moratuwa and involve in sustainable engineering practices.

Eng. Ruwan Nagahawatte has more than 15 years of experience in designing, construction and operation of power generation system in Sri Lanka. He is graduated from University of Moratuwa and involve in sustainable engineering practices.